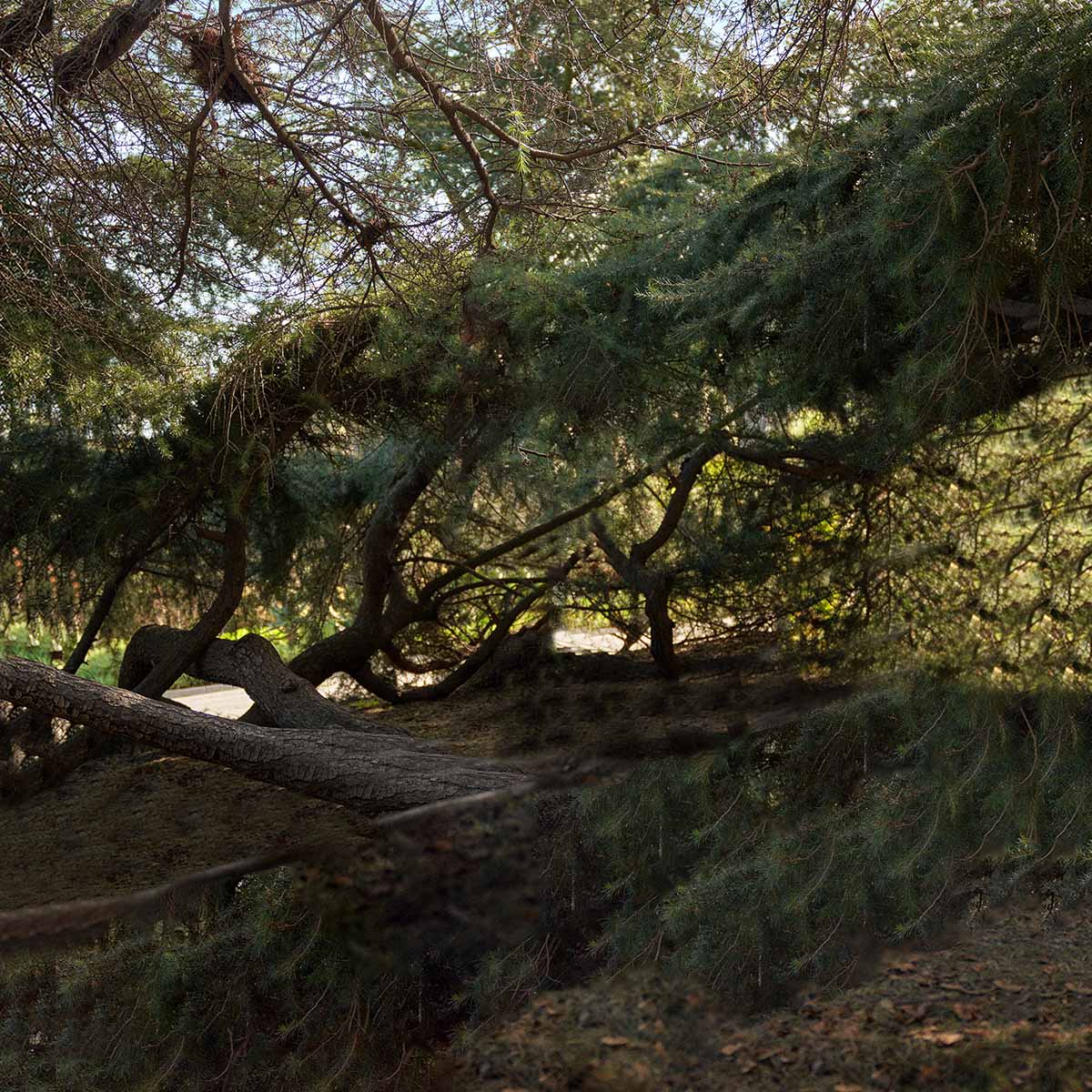

Protect what has

protected us.

This is Home

The outdoors is a place where we all thrive. We plan to keep it that way. It's our goal that by 2025, everything we make will include recycled, organic, or renewable materials.

Shop Sustainable Products

70% recycled mesh upper. ✅

100% recycled laces. ✅

Moab Flight helps you feel good from from the inside out when you hit the trail in shoes trusted by 50 million feet and counting.

With a 100% recycled mesh lining and laces, the lightweight Moab Speed brings conscious footwear to your most anticipated hike.

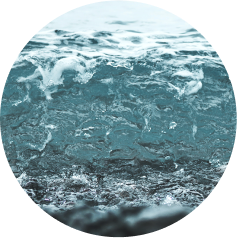

Made for days spent in and around the water. Slip into a pair of Hydro Mocs made with BLOOM™ algae and find yourself at ease knowing that 93 liters of water is cleaned and restored to the environment with each pair.

When you slip into a pair of Hydro Mocs made with BLOOM™ algae, you can rest assured knowing that the air is cleaned of CO2 with each pair.

Less water. Less energy. 100% recycled laces and so much more. Same trail favorites, just more conscious.

Our seven sustainability goals to achieve by 2025:

100%

of our products will contain organic, recycled, or renewable materials

100%

responsibly-sourced apparel

Reduce shoe and

apparel samples by

50%

Reduce Plastic

Packaging

Reduce water waste by

40 Mil. gallons

Complete

10K

volunteer hours

Save

300K

pairs of shoes from

ending up in landfills